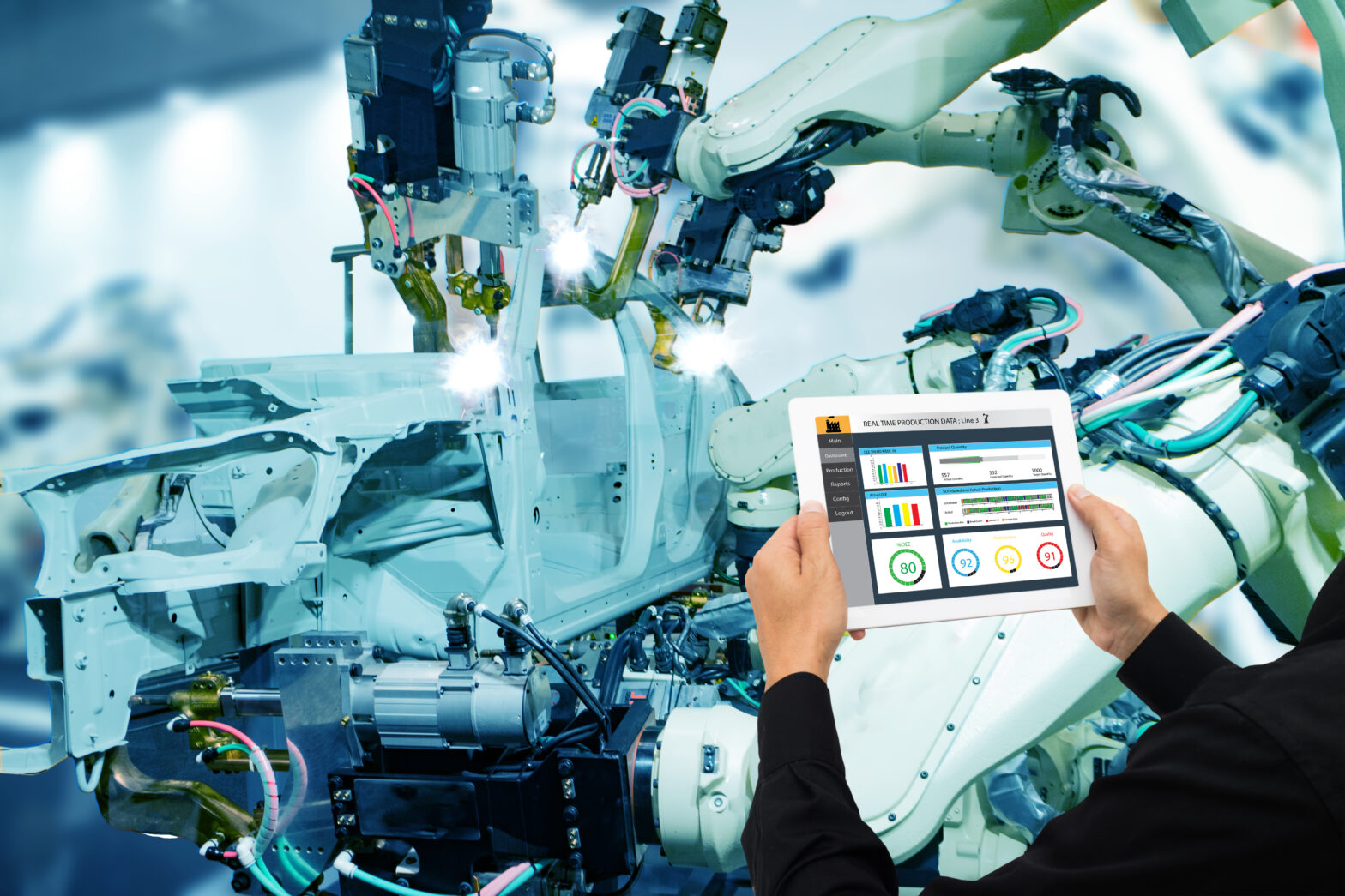

Machine-to-machine integration and the Industrial Internet of Things (IoT) are reinventing the manufacturing industry. They’re giving birth to the smart factory that is connected, intelligent and aware — enabling newfound levels of productivity and predictability.

Manufacturers have been collecting information from across the manufacturing floor for decades, but in recent years the cost of implementing smart sensors has gone down significantly, and conversely, analytics capabilities have grown extensively.

As a result, today there is technology to go beyond data capture to extrapolate near real-time insights to inform and optimise processes for better outcomes. This is the nirvana of the smart factory.

>See also: Edge computing is the gateway to smart manufacturing

What can manufacturers gain from getting more in tune with machines? Plenty.

In its landmark study, The Internet of Things: Mapping the Value Beyond the Hype, the McKinsey Global Institute proclaimed the greatest potential for creating value from the IoT for manufacturers will be in operations optimisation, making the various processes within the factory more efficient. This includes using sensors, rather than human judgment (and human error), to adjust the performance of machinery.

It also involves use of data from production machinery to adjust workflows to eliminate unproductive practices, capacity erosions, inefficiencies and line performance bottlenecks. This is done by remotely tracking, monitoring, and adjusting machinery, based on sensor data from different parts of the plant (and even across plants). Researchers say IoT applications in operations optimisation have the potential to create value of $633 billion to $1.8 trillion per year in the factory setting in 2025.

Monitoring machines to harness and understand data can help manufacturers optimise machine performance by enabling more proactive, predictive maintenance. Using sensors to determine when machines need service can prevent breakdowns and save on routine maintenance costs.

Connecting equipment with sensors through a common platform can provide invaluable data about the ongoing condition of equipment that can be analysed to predict potential points of failure for equipment breakdown and production shutdown. In the event a breakdown does occur, organisations can analyse this data to determine root cause and take corrective actions to prevent future occurrences.

>See also: Smarter and faster – why manufacturers must embrace the IoT

Monitoring can also deliver improved quality and production throughput, through greater uptime and overall equipment effectiveness, less scrap and rework, and lower operating costs.

Additionally, these efforts can support continuous improvement initiatives and contribute to heightened workforce engagement, by keeping front-line workers and management informed for improved responsiveness, ownership and accountability.

Remote monitoring, tracking, and control of equipment and workflow also can support additional efficiencies in optimised energy usage. The cost savings in this regard can be considerable — especially in instances when energy prices rise precipitously.

Process control and traceability are essential, and the IoT can “level up” manufacturers game in this area. Using sensor technology, manufacturers can then track serialised and non-serialised components as they are received, warehoused and used to construct sub-assemblies and finished goods.

Prior to the start of processing, traceability and production control can ensure the correct part is being run, the correct machine program type is being used, that the part was not previously rejected as bad, that the part is at the correct operation (no process was skipped), and that parts are not run a second time at the same operation, and that part orientation is correct for processing.

>See also: IoT and manufacturing: more than streamlining the factory process

Inventory represents a significant cost for most manufacturers and an IoT approach can reduce the potential of excess inventory via automated replenishment – where machines on the factory floor can signal when quantities are low and even “order” more raw materials to ensure the line never shuts down, and that inventory is managed in the most just-in-time, cost-effective manner.

Via the IoT, manufacturers gain powerful capabilities to understand the overall health of operations minute-by-minute, to take advantage of opportunities and mitigate threats to support growth and profitability in today’s fast-moving, ultra-competitive and highly complex regulatory manufacturing environment.

However, the velocity and volume of data on the manufacturing floor can be a hardship to manufacturing organisations that do not have the right technology infrastructure in place. Having the right software foundation to capture, analyse and act is critical.

A unified reporting framework to simultaneously view and easily discern information from multiple, disparate data sources is just the beginning. Manufacturers need to have the operational agility to act on this data and apply these insights across the entire product lifecycle — from design, through engineering, manufacturing, delivery, and service — to deliver immediate and actionable information to the necessary departments and functions with greater speed, accuracy, and efficiency than ever before.

>See also: 7 industries that will be radically changed by the IoT

Manufacturing execution systems (MES) and enterprise resource planning (ERP) systems take on newfound relevancy in the IoT era, to help manufacturers realise the full value-add of big data/IoT initiatives, to contextualise data and integrate it into downstream process flows.

Functioning as the fabric that connects people, processes, data and things in an intelligent and strategic manner, MES/ERP systems allow manufacturers to create value from new data streams to succeed in achieving their most critical objectives.

Sourced by David York, regional vice president, UK and Ireland, Epicor Software