The UK’s energy challenge has been debated for too long. While energy production is changing, with the decarbonisation focus resulting in more renewables, it is also prompting a rise in small scale generation that is significantly reducing generation flexibility.

This is creating a new set of problems for the National Grid, with different geographic areas experiencing varying levels of over and under supply.

In response, companies are being actively incentivised to embrace demand side response (DSR) by lowering or shifting electricity use at peak times.

However, the financial return for many simply does not outweigh the operational risks.

The conversation has to change – to get industry buy in, the focus has to be on operational benefits first.

An emphasis on leveraging real-time refrigeration data to improve food quality and safety is set to make energy shifting a reality within cold food retailing.

Energy demands

From Hinkley Point to wind farms and fracking, the UK is looking at a raft of options to address escalating energy demands and an ageing network.

However, with the National Grid generating margin of just 5.1% during winter 2015/16 and an increasingly fragmented production model, innovative solutions that can address both short and long term national and local energy requirements are long overdue.

>See also: Five smart solutions transforming the energy industry

The introduction of demand side response (DSR) tariffs was designed to incentivise businesses to lower electricity use during periods of peak demand.

However, while some businesses have been able to take advantage of DSR by swapping over from the National Grid to stand-by generators on demand, there are far more organisations where the business risk simply does not justify the return that could be generated in reduced energy tariffs.

For example, while up to 14% of UK electricity is consumed by cooling alone, no retailer will embrace DSR by turning off refrigeration without full confidence that it can do so without compromising either food safety or quality.

Furthermore, the challenge is not just over demand – over supply is also a major problem for the Grid, which operates in a model that simply cannot shift power between geographical areas.

As a result, while counties such as Lincolnshire are often running very close to capacity, Cornwall’s wind turbines often create an excess supply.

The challenge therefore is not simply to entice companies to embrace DSR to reduce demand at peak times, but also to utilise over supply, and on a local rather than national model through energy shifting.

Business first

There is no doubt that the DSR theory is compelling by enabling a reduction in network constraints, while supporting broader plans to integrate large-scale renewable energy loads with inconsistent generation output.

However the sporadic uptake to date underlines the need to shift the focus away from energy-first towards a business-first approach; and one that supports energy shifting as much as energy reduction.

How, for example, can a food retailer respond to the Grid’s request to reduce consumption within thirty seconds to achieve the primary DSR tariff? Or even the thirty minutes associated with the secondary DSR tariff? What about increasing consumption in times of over supply? Can either be achieved using the existing cooling management system – and what is the implication for food quality and safety?

>See also: Big data at British Gas: a new era of energy

Turn this model on its head and it becomes far more appealing. Enabling food retailers to actually improve food safety and enhance food quality by adopting more sophisticated cooling management is clearly compelling to an industry that experiences upwards of 30% wastage annually.

The fact that a more sophisticated approach to managing cooling in real-time can also enable retailers to take advantage of DSR and help in the management of national power resources is an added, albeit significant, benefit.

DSR opportunity

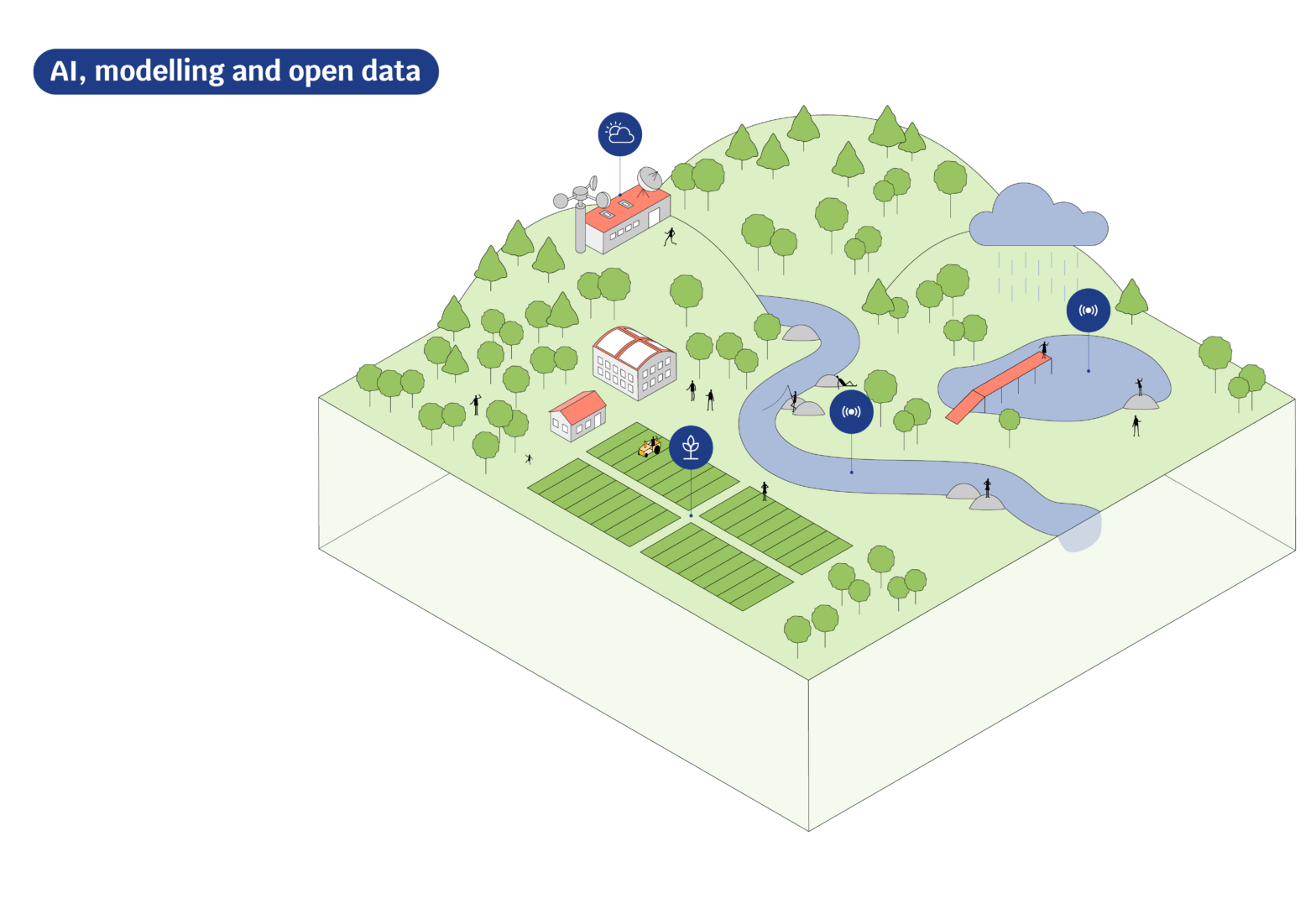

Today, the collection of billions of dynamic data points from thousands of devices every minute of the day is being combined with edge-based processing and analytics to embrace a far more sophisticated model for food cooling.

Rather than following the traditional model of chilling all food to the temperature required by the most sensitive product – i.e. meat or ice cream, with the ability to manage cooling in real-time, retailers can now embrace effective food specific cooling models.

As a result, the expense of over cooling is massively reduced and the risk of compromise to food quality caused by excessive chilling, especially to dairy, is removed.

What is really exciting to those looking to build flexibility into the UK’s power resources, is the chance to extend this model to switch refrigeration on and off in response to the demands of power systems such as the National Grid, not just nationally but locally, to support energy shifting requirements.

With the thermal inertia of refrigerated products providing an operational buffer that can be used to reduce demand at peak times and resume cooling when demand is low, there are huge opportunities to reduce – or increase – consumption in response to the demands of the Grid.

>See also: IBM and Energy Department to build ‘grid computer

By changing the profile of energy consumption in any given physical location or asset to respond to the overall capacity within the Grid, while still ensuring devices are operating efficiently, organisations have the chance to reduce consumption and negotiate lower costs with power suppliers.

Indeed, the whole concept of energy shifting will demand new contractual arrangements that reflect local, as well as national, demands.

Conclusion

Clearly, given the high demand placed on the National Grid by cooling, there are huge opportunities to address cold chain energy consumption within the food retail industry.

Indeed, given the size of the refrigerated food chain, this model can be extended beyond retailers to include distribution and transportation providers.

However, it is the re-focus from energy-first to a business-first model that is really enabling these long overdue developments.

>See also: How the Internet of Energy will usher in the hybrid home

The ability of food retailers – and other organisations – to gain measurable business benefits by leveraging real-time machine data to drive operational improvement is compelling.

It is then building on that confidence to support the highly sophisticated demand response models that will be key to reducing consumption and creating that essential flexibility in the UK’s increasingly fragmented power network.

Sourced by Edward Porter, head of dynamic monitoring at IMS Evolve