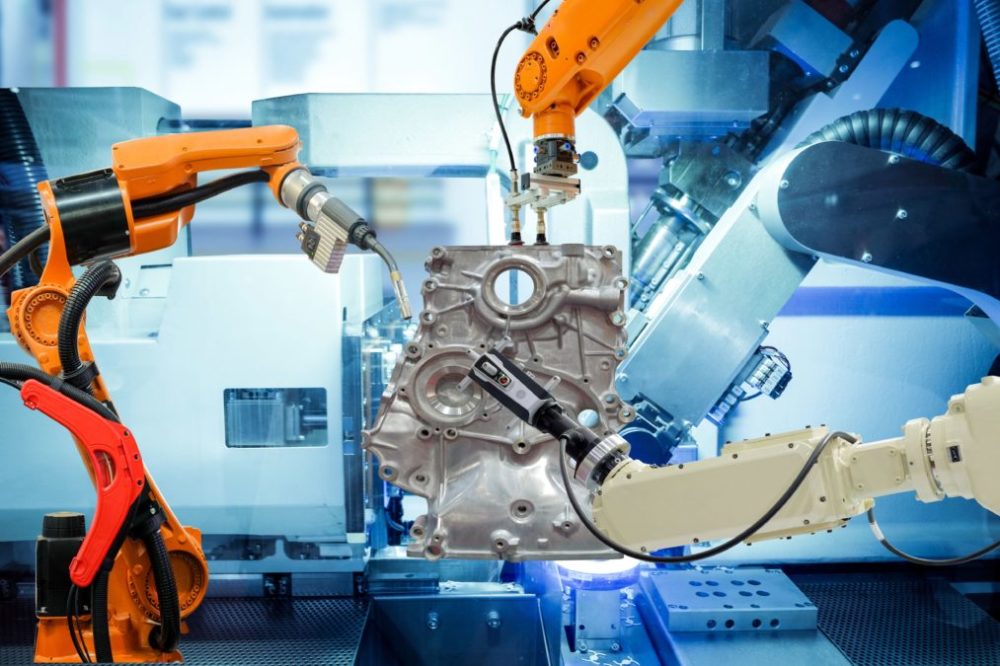

Industry 4.0 has become the Holy Grail in manufacturing. Faced with customer demands that are evolving faster than ever before – and the pressure of ongoing economic uncertainty – manufacturers are turning to digital transformation in pursuit of the new era of manufacturing. From more efficient operations to a more in-depth knowledge of customers and bringing new products to market at speed: Industry 4.0 promises to help manufacturers meet the needs of the future.

The financial benefits could be significant. Manufacturers in EMEA believe that their digital investments will drive revenue growth of 13% over the next five years, while the sector’s digital leaders are already deriving over 50% of their revenue from digitally-enhanced or digitally-led products and services.

>See also: Industry 4.0 and the cloud: a match made in heaven

Manufacturers are becoming more dependent on digital technology, but with this reward comes risk. The proliferation of digital has significantly increased the challenges for IT teams charged with ensuring business continuity, while making IT downtime more damaging than ever.

Digital from design to distribution

Digital technology is becoming the cornerstone of every part of the manufacturing process. From the early stages of design and development, through to operations and finally distribution: every stage in the manufacturing lifecycle is underpinned by digital platforms.

Stakeholders throughout the manufacturing supply chain are benefitting from an increasingly sophisticated digital life. Within the business employees can use the technology to be more collaborative and mobile, while partners, suppliers and distributors are better integrated and informed.

>See also: Is the UK manufacturing sector prepared for Industry 4.0?

The manufacturing sector is quickly moving towards the point where virtually everything will depend on digital technology. In a fast-moving and highly competitive environment, making the best use of digital – and acting on the insights it delivers – could be core to securing a place in the future. However, while digital presents incredible opportunities, it also presents more significant challenges than ever before.

With great power comes great responsibil-IT

Manufacturers’ growing dependence on digital is putting IT teams under enormous pressure to ensure business continuity. However, the sheer scale and complexity of manufacturers’ digital lives make this a growing challenge. Data growth in itself presents potential pitfalls, from determining where and how it is stored to ensuring it is properly protected and quickly recoverable in the event of a disaster.

IT teams are also faced with significant external threats. Cyber-attacks are increasingly prolific and sophisticated; the WannaCry ransomware attack of last year underlines the sheer scale of the damage that an attack can do. The growing use of connected devices and the IoT is creating even more points of entry for IT teams to manage, especially if employees use their own devices.

>See also: How can firms embrace the digital to achieve growth?

Old backup technology can also present a serious hindrance. Volvo Car Benelux, for example, had relied on individual dealerships backing up their physical servers on site to tape. However, the organisation found this approach increasingly unfeasible, due to the cost of purchasing additional tape drives, the risk of human error and the lengthy process for data recovery. All of these factors make ensuring business continuity a challenging undertaking.

The damage of downtime

Added to-these pressures is the fact that any IT downtime can be extremely damaging for manufacturing businesses, where uninterrupted access to equipment, applications, data and processes is vital. Outages at any point in the process can cause havoc further down the line and have knock-on effects on staff morale, customer loyalty and the business’ reputation. The financial damage, both in immediate loss and opportunity cost, can be widespread and long-lasting.

As a result, the business’ demands for recovery are high. Manufacturing companies are especially vulnerable to an availability gap, where the IT team cannot meet the recovery requirements of the business. This is not uncommon across all industries; 80% of IT decision makers suffer from an availability gap, resulting in total costs of $21.8million per year. But in a sector where continuous operations are critical, business continuity must be a particular imperative.

>See also: Anticipating downtime will be business’ next competitive advantage

Delivering data availability in four steps

Data availability then must be a priority for manufacturers. But how can IT teams deliver it in practice?

- Create a viable business continuity plan. While creating a strategy for data availability may seem straightforward, it’s incredible how many plans seem adequate until they’re tested – and fail. IT teams must develop a strategy that protects every critical business unit across the supply chain, without negatively impacting the experiences of employees or partners. Once the plan and relevant systems are in place, stress test it regularly to identify any pain points before a disaster takes place.

- Manage your data intelligently. Ensuring the availability of data and applications must be the primary imperative of the business continuity plan. That means using solutions designed to address the continuity challenges of highly virtualised and cloud-enabled manufacturing environments. Selecting a data availability solution that can achieve a recovery time of less than 15 minutes for all applications and data should meet the requirements of most parts of the business, even when a disaster strikes. Volvo, for instance, backed up its on-premise virtual machines using the latest data availability solutions. This ensured that in the event of a fire or other catastrophe every dealer could recover a failed VM within minutes to minimise the impact of outages on operations.

- Keep your business’ eyes open. Visibility and ongoing monitoring are vital to preventing issues and responding to them when they occur. Real-time monitoring and reporting on virtual environments enable IT teams to anticipate and address potential problems before they affect operations. Similarly, end to end visibility for both physical and virtual machines helps to prevent possible failures of any type of application or system. Having this clear picture of events can also save businesses time and money in meeting compliance requirements.

- Protect your present and your future. Two-thirds (66%) of IT decision makers say that IT downtime is hindering their digital transformation efforts. It’s critical that businesses balance the introduction of new technology with ensuring data availability, to avoid hindering the ongoing operations of the organisation. Data availability solutions can enable IT teams to test applications and upgrades before they go into production. It’s also possible to manage, migrate and restore data across a physical, virtual and cloud-based infrastructure without complex configurations or additional hardware investments – minimising the operational costs of introducing new technology.

A foundation for Industry 4.0

Digital transformation is bringing immense benefits to manufacturers and progressing towards Industry 4.0 will be critical for organisations to secure their place in the future of the sector. However, as manufacturers’ dependence on digital grows, business continuity is becoming more and more of a business imperative. Using the latest solutions, IT teams can build a reliable foundation of intelligent data management to underpin their digital systems. In this way, businesses can ensure that they can take advantage of new technologies with confidence and truly embrace Industry 4.0.

>See also: Business in Industry 4.0 – paving the way for change

Written by Calum Roberts, Director of Enterprise Sales, Veeam UK and Ireland