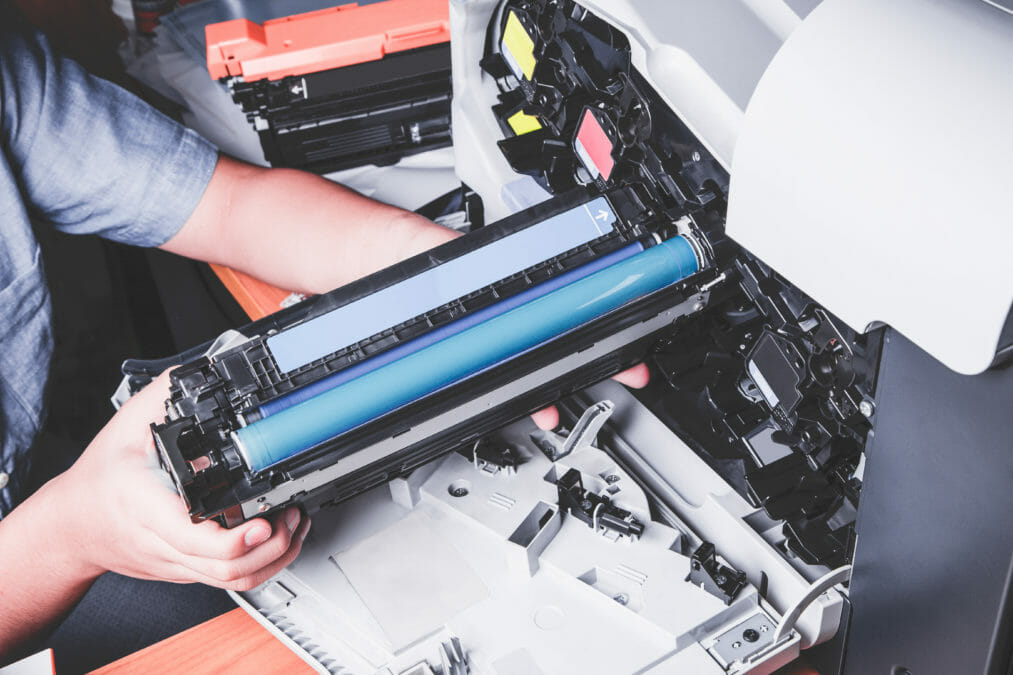

This partnership between Ricoh and Microsoft has allowed the former to cut toner loss by 0.9 grams at its factory in Telford, Shropshire.

Ricoh can now accurately determine how much toner needs to be filled into each bottle; this can change depending on room temperature and humidity, as well as other factors.

The imaging and electronics company are leveraging solutions available on Microsoft Azure, including IoT Hub, Stream Analytics, Databricks and DevOps, in order to ensure efficient usage of toner.

It’s predicted that the use of Microsoft AI by Ricoh will save the company over £200,000 a year.

Richard Aston, digital operations engineering manager at Ricoh UK Products Ltd, said: “We import bulk toner produced in Japanese factories, which we use to fill anywhere from 400,000 to 900,000 toner bottles per month in the UK.

“Every bottle has a lower threshold and an upper threshold, and there is a lot of automation and processing equipment used in filling them. We wanted to leverage Microsoft’s machine learning technology and our data to improve the process.

“We are now planning to roll it out to the rest of our toner filling lines. Then, we will look at other areas where we can deploy this technology and data-first approach.”

Additionally, Ricoh has managed to broaden its workforce’s skillset as the company continues to implement AI into its practices, allowing employees to get the best out of the data it generates.

How can organisations use data effectively, according to corporate VP at Microsoft Azure

A data scientist has been hired to help bolster the collective digital skills of Ricoh’s workforce, with the recruitment of a data architect also planned.

“Microsoft has been very supportive in terms of upskilling us,” Aston continued. “I’ve been connecting with a lot of the data and analytics experts there.

“Microsoft is investing in AI, and it gives us a lot of confidence that we’re putting our faith and trust into a company that will deliver.”

[emailsignup]