Society is in the midst of a ‘Fourth Industrial Revolution’. According to the man who coined the term, Professor Klaus Schwab, founder and executive chairman of the World Economic Forum, significant advancements in digital technology are fundamentally changing the way people live, work and relate to one another.

Businesses across all industries are adopting new technological innovations in order to gain a competitive advantage.

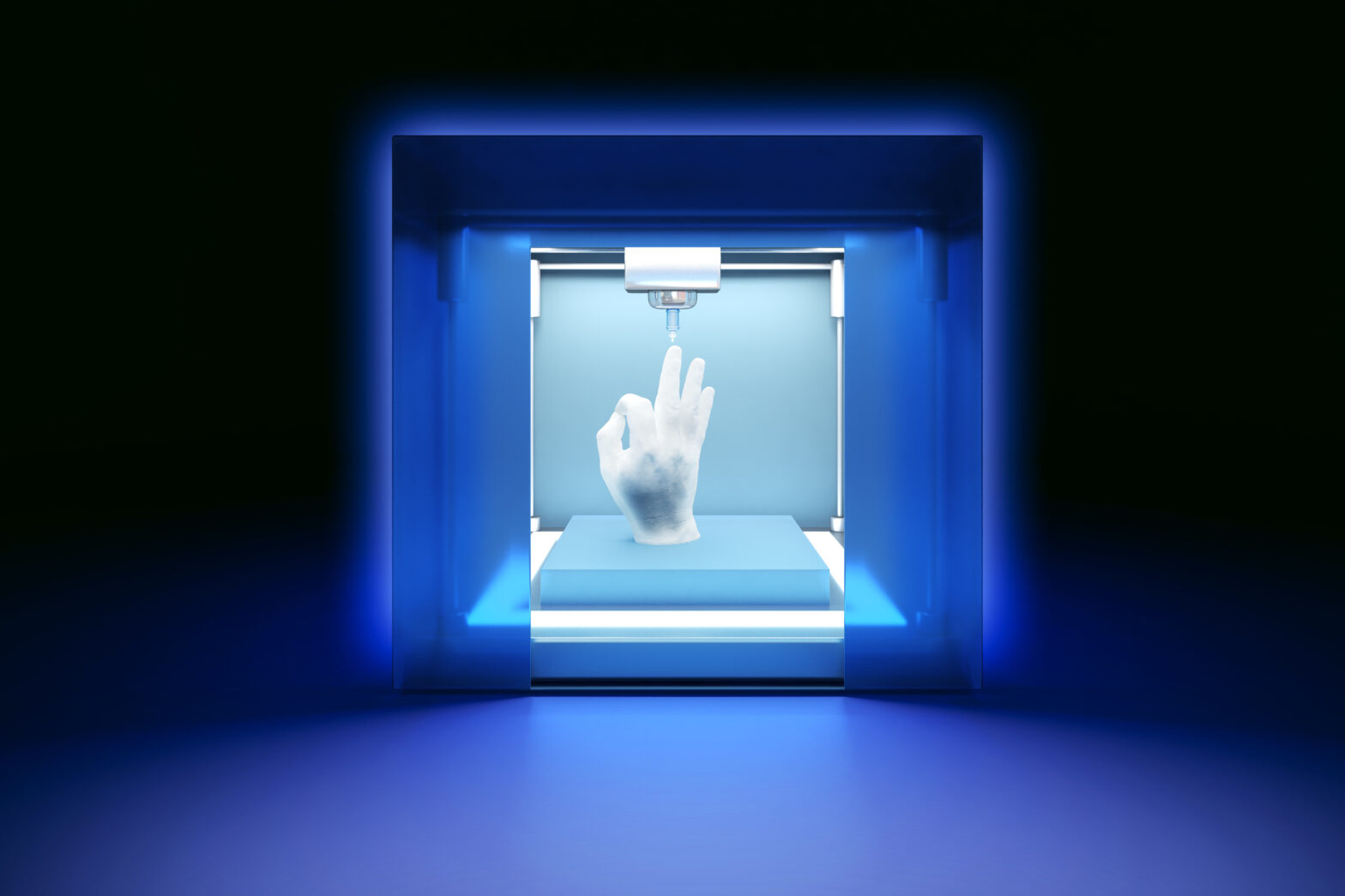

Advanced manufacturing technology such as automated 3D printing and CNC (computerised numerical control) machining is transforming the medical industry, for example, offering new opportunities to address the different challenges faced by providers of healthcare and medical devices, and directly improving the quality of many patients’ lives.

CNC machining, in which computers are used to control high-speed milling and turning tools, has been employed by the University of Houston in the creation of custom-machined aluminium-joint housings for a powered exoskeleton, part of a robotics systems designed to help paraplegics walk again.

>See also: Renewed confidence through digitalisation and advanced

3D printing can enable the production of increasingly complex parts in ever finer solutions, meaning that implants and prosthetics are now being tailor-made for individuals.

Someone with extremely limited mobility can now use a personalised 3D-printed joystick to control their wheelchair, for instance, customised bionic eyes are helping people with profound vision loss to recover some degree of sight through using a retinal implant, and hearing aid manufacturers now use a form of 3D printing to create custom-designed hearing aids to the exact geometry of an individual patient’s ear.

Proto Labs was recently called upon to support the development of a tailor-made cranial implant. It worked closely with the designer to manufacture the implant to meet a patient’s very specific needs, in less than three days.

Precise requirements

A patient was in need of a particularly large cranial implant as a result of surgery following cerebrovascular surgery. Buenos Aires-based medical device manufacturer Novax DMA was assigned with developing and building an implant that would meet some very particular requirements.

Not only did the implant need to fit perfectly, but it also had to integrate with the patient’s biological functions, minimising heat transfer into the brain tissue, and be permeable enough to accommodate dissipation of both heat and liquid.

>See also: The future of digital manufacturing

Concerns were raised that titanium, the material typically used in medical implants, might not meet all of these criteria as, being a metal, it conducted heat and was not sufficiently permeable.

However, by employing a process of additive manufacturing, in which a laser was used to apply the titanium a layer at a time, Novax DMA was able to create a lattice-shaped implant that was not only an exact fit to the skull, but allowed the bone to grow and enabled liquids to permeate.

What’s more, the design had an insulating effect, which minimised the conduction of heat into the interior of the cranium.

Time is of the essence

It goes without saying that patients need to receive their implants as quickly as possible, so time was a critical factor.

Work began on the construction and manufacture of the implant as soon as the final information about its dimensions had been received.

>See also: AI can transform the medicinal industry

Preparing this data and manufacturing the implant itself was carried out in around two and a half days and, after various procedures around logistics and co-ordination, the implant was in the hospital within just three weeks.

The operation to fit the implant was over in 90 minutes, and the patient left the clinic only two days later. The wound healed within three weeks of this and the patient has experience no complications or ill-effects since.

Rapid evolution

Technology is evolving and developing at a rapid pace. The digital revolution means that ideas created on a CAD screen can now quickly become reality within a matter of days.

The speed and potential for personalisation that advanced manufacturing allows is transforming the medical industry for the good, addressing challenges in previously unimaginable ways, and enabling patients to live better, healthier – and longer – lives.

Sourced by Stephen Dyson, head of industry 4.0, Proto Labs