Worldwide shipments of 3D printers will reach 496,475 units in 2016, up 103% from the predicted 244,533 units in 2015, according to Gartner.

The analyst firm predicts 3D printer shipments will more than double every year between 2016 and 2019, by which time worldwide shipments are expected to reach more than 5.6 million.

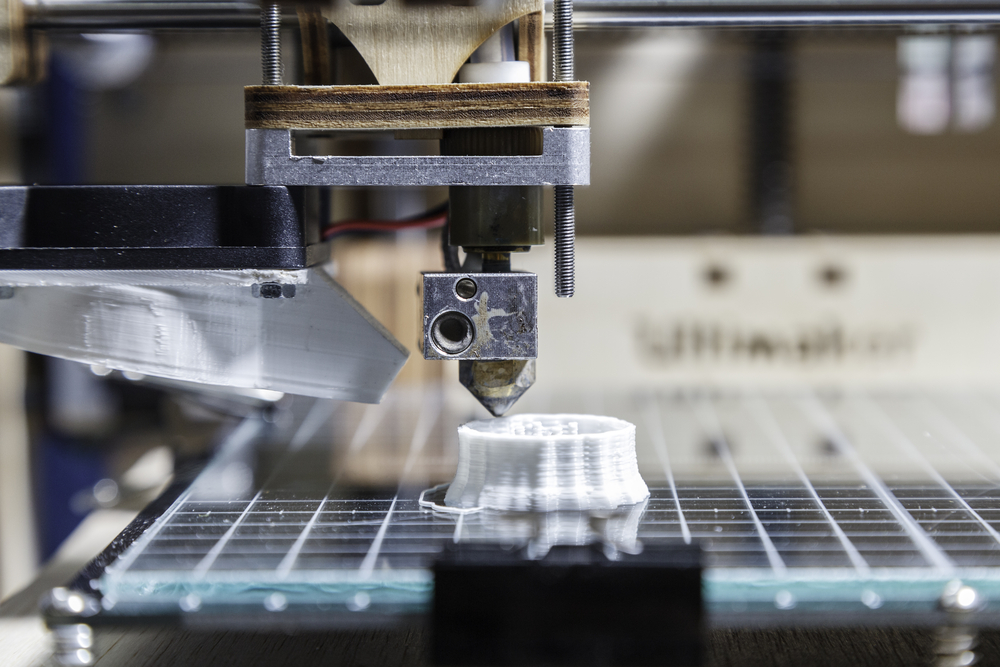

Seven technologies constitute the 3D printer market, with material extrusion predicted to lead 2015 shipments at 232,336 units, increasing to 5,527,493 units in 2019 (97.5% of the total) – largely due to the sales of low cost, entry-level material extrusion printers.

Average selling prices vary by technology and market. Each market has different dynamics, including the mix of devices, prices and buyer requirements that drive the average for all 3D printers in a given technology. Directed-energy deposition printers are the most highly priced, followed by powder bed fusion printers.

Worldwide shipments by price band are affected by the 3D printer technologies represented within them. Of particular note are the up-to-$1,000 and $1,001-to-$2,500 bands, which are dominated by material extrusion devices.

>See also: The third dimension: 3D printing in the enterprise

3D printers costing less than $1,000 will make up 25.5% of the total of these two price bands in 2015, but will grow to 40.7% of the $1-to-$2,500 range by 2019.

The primary market drivers for consumer 3D printers costing under $2,500 are not household purchases but acquisitions of low-cost devices by schools and universities. The primary enterprise 3D printer market drivers are the finished-piece quality and material advances.

“Rapid quality and performance innovations across all 3D printer technologies are driving both enterprise and consumer demand, with unit shipment growth rates for 3D printers increasing significantly,” said Pete Basiliere, research VP at Gartner. “The 3D printer market is continuing its transformation from a niche market to broad-based, global market of enterprises and consumers.

"Enterprise 3D printers can not only prototype new products and produce tools and fixtures that are used to make other items, but also print high-quality, short-run finished goods.”