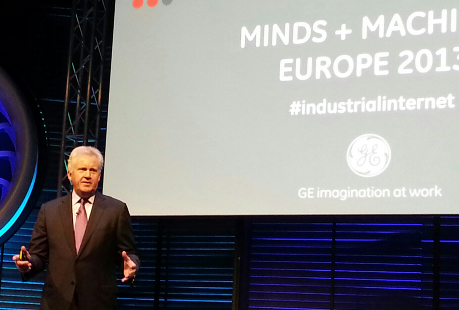

The application of big data in industrial settings is driving a productivity revolution, according to Jeff Immelt, CEO of industrial conglomerate General Electric, speaking at the ‘Minds and Machines Europe’ event in London’s Battersea Power Station today.

The forum, hosted by GE, brought together thought leaders from across business, technology and academia to discuss the implications of the “industrial internet.”

Immelt described how analytics combined with materials science and “intelligent machines” equipped with sensor technology to harness the power of industrial data in real time is driving growth for GE across all their sectors including healthcare, energy, infrastructure, locomotive and aviation.

GE gained around $45 billion in revenue last year through the use of analytics to automate processes, optimize performance, eliminate downtime, and predict when a machine or component will fail, he claimed.

“What we’ve envisioned here is a way to enhance and drive capability with our existing GE interface with our customers,” said Immelt.

“This is an example of a domain based company that’s moving upstream into analytics instead of the other way around.”

But it’s not just talk – GE has invested heavily in the “industrial internet” over the past few years, including into collaborations with Pivotal and Accenture.

GE uses Hadoop software to manage time-series data, allowing it to scale data across multiple nodes, helping to manage the influx of tiny pieces of data that comes in almost constantly.

"Small performance changes can drive massive economics in the marketplace and for our customers," said Immelt.

Immelt claimed that improving just 1% of fuel performance a year on aircraft engines through continuous real-time data monitoring saves customers $2 billion.

Gas engines connected to a score of sensors can capture data every 30 seconds. Software then evaluates component conditions and maintenance needs, allowing for remote monitoring and early diagnosis of problems. One gas engine can produce up to 32 terabytes of data for analysis a year.

Healthcare equipment, such as MRI scanners, can use software connected to GE field engineers to collect information on performance over time and remotely solve issues, leaving clinicians more time to provide essential care and reducing downtime.

Marco Annunziata, chief economist at GE, described GE’s vision for the “internet of machines” as the third revolution that will spur the next wave of economic growth, building on the industrial and internet revolutions of the 19th century and the 1990s.

This will spur “a new wave of productivity that will enhance economic growth across the economy,” said Annunziata.

“The industrial internet is bigger than GE and bigger than industry.”